Complete Air conditioning repair guide

HVAC industry is very wide and vast industry in the field of engineering and HVAC industry provides opportunities to technically qualified people to adopt this industry as a carrier path. In this article one can learn easily the techniques to repair HVAC systems and can easily understand AC repairs.

This article is very useful for beginners who wish to learn the

techniques to repair air conditioners. There are different air conditioning applications

as following

Following are different types of air conditioning systems.

Window air conditioners

High wall air conditioners

Cassette type air conditioners

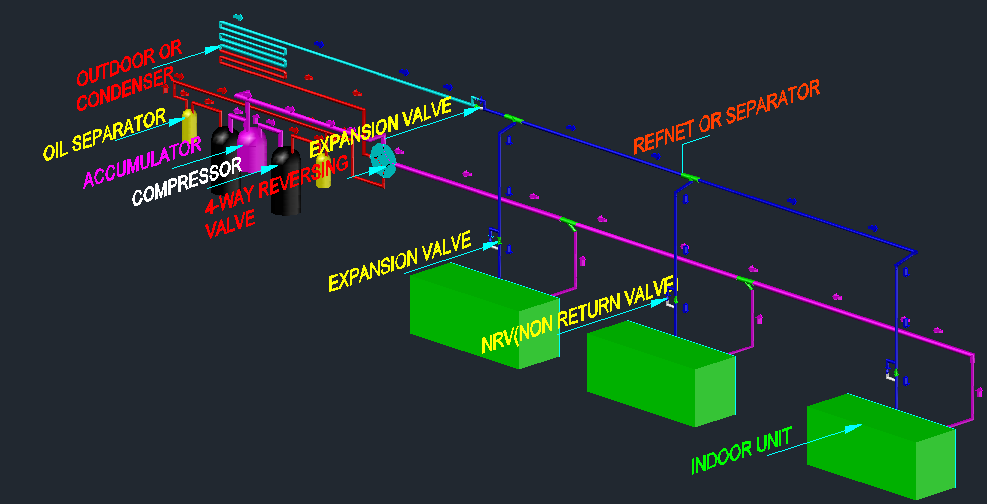

VRF/VRV systems

Packaged air conditioners

chillers

Before starting the HVAC repair course let us know about the tools which are common for all types of air conditioners installation and repair.

Gauge Manifold set: - In HVAC repair field the gauge manifold set as shown in figure below is used to determine the pressure of refrigerant in an air conditioner. Without gauge manifold set we can’t top up the refrigerant accurately as per system requirements. The gauge manifolds are compatible with different kind of refrigerants.

Flaring tool or Die in HVAC: - Flaring tool is used to widen the diameter of copper pipe to make a joint with flare nut as shown in figure below. Flaring tool is designed to use for copper pipes of different diameters. It is easy to use just insert the copper pipe in same diameter mentioned on die set. The face of the copper pipe which is going to be flared should not be out of the hole more that surface of die body.

Pipe cutter or Tube cutter in HVAC: - Pipe or tube cutter is used to cut the copper pipe. The copper pipes are soft and this cutter is designed to cut the pipe easily without causing any damage to pipe.

Pipe Bender: - A special bender is used to bend the pipe according to the pipe route. As the copper pipes that are used in HVAC applications are soft and if we will try to bend it without bender then pipe will be pinched or damaged which may cause obstruction in refrigerant flow. So to avoid this problem special bender is used. There are two types of benders spring type and rigid as shown in figure below.

Brazing set in HVAC: - Brazing set is used to join copper pipes of big diameters, to repair a leak and to replace the parts of air conditioners. On big diameter pipes flaring joints can’t be made so brazing is done to make a joint. Brazing set consists of oxygen, Acetylene gas, Brazing torch and trolley as shown in figure below.

Ampere meter: - Ampere meter or clamp meter is very important to check the electrical parameters while repair or commissioning of system.

Vacuum pump in HVAC: - Whenever we install a new air conditioner or when we change any part while repair of as air conditioner we need to charge the system or top up the system with refrigerant. But before charging or top up we need to vacuum the air conditioner piping network to make it free of air, moisture, dust/dirt etc.

Leak detector: - Leak detector is used to find out the exact point of gas leakage in an air conditioner. But mixture of soap and water can also be used to detect the leaks and this method is commonly used to find a leak.

Refrigerant recovery machine: - The refrigerants are expensive and

when we need to change any part of air conditioner we have to save the

refrigerant from escaping to atmosphere. The recovery machine can be used to

recover the refrigerant and store back into the cylinders.

Air conditioners are equipped with very expensive components and to protect them from any damage safety switches, relays, sensors, overload protectors etc are provided in the system. All the safety devices are connected in series instead of parallel so that all components of system go off. Whenever something wrong happens with functionality of system these safety devices break the circuit and whole system is shut down and this shut down is called tripping.

Most common Tripping faults in window, split high wall and cassette AC.

1. Tripping due to H.P or L.P safety switches

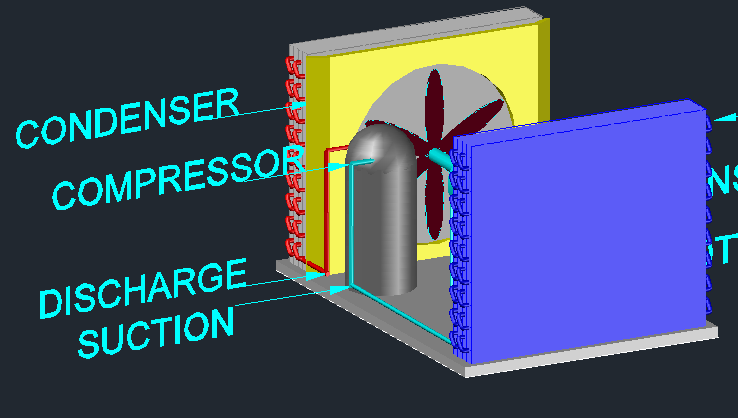

This tripping is caused by increase or decrease of refrigerant pressure in refrigerant circuit. If there is a leak of refrigerant in an air conditioner then L.P (Low pressure switch) will cut off the power supply and if the system is overcharged with refrigerant or there is any choking in the copper pipe circuit then pressure of refrigerant can go high and power will be cut off from H.P switch. You can easily see these switches on copper pipes near compressor. The L.P switch is installed on suction line and H.P switch is installed on discharge line.

2. Tripping due to surge in current or amperes

Compressors, condenser fan and indoor fan or evaporator fan work with electrical motors. During high ambient temperatures or loss of cooling from open windows or doors the work load on these components increases as system runs on its full capacity to achieve indoor set temperature on remote control. When system fails to achieve set temperature and run continuously for long time the components start to take high amperes and the system is forced to cut off from overload protectors for safety of the system.

To avoid this problem the doors and windows should be close during running air conditioners.

3. Tripping due to choked air filters

In all air conditioners air filters are used to keep the air free from contamination and dust. If these filters are not cleaned up at the time of scheduled maintenance then contamination will choke the air flow and when the air will not be able to pass through the coils the temperature on coils will go significantly low and ice formation will start to happen. In this situation compressor will start to take high amperes and system will be cut off from overload protection.

4. Communication failure

Air conditioners are equipped with electronics PCB (Painted

Circuit Board) and these PCBs control the automation functionality of air

conditioners. Air conditioners may not work properly if PCB is not properly

working. If there is no proper communication between indoor and outdoor it

means PCB may be faulty and needs to repair or replace.

5. Grounding of any component

During high ambient temperatures or cooling loses in the space the compressors and fan motors have to run continuously to achieve the indoor temperature. But due to high work load the electrical motors in compressor or indoor/outdoor fans can burn their motor winding and may result into grounding.

With the help of Clamp meter it’s very easy to diagnose the

grounding of components. Just adjust the probe on continuity sign as shown in

figure below and check the electrical terminals of compressor or fan motor by

touching on lead of the meter to all terminals one by one and other on the body

of the air conditioner, if you get beep sound with any of the terminal it means

that component is grounded and needs to repair or replace.

6. Faulty Expansion valve

Expansion valve has a diaphragm which is connected to valve stem as shown in figure and due to high frequency of open and close function the pressure on the diaphragm increases and can break it. In this case one has to change this expansion valve.

7. Driers failure

There are many types of driers which are used in air conditioning and

refrigeration systems. These driers keep the refrigerant free from moisture and

contamination particles. These driers have certain life span and need to

replace on scheduled time period. If these driers are not changed on scheduled

time then refrigerant will run in the system with moisture and contamination which

can reduce the performance of system.

1.