What is air conditioning?

In very simple words term air conditioning is a process to create human comfort zone. Air conditioning is not only concerned to temperature control but in this process all psychrometric properties and parameters of air are considered. The basic principle of thermodynamics is, heat energy always transfers from hot substance to cold substance. And this basic principle is applied in air conditioning process as well. The heat is abstracted from the conditioned space and released outside to the atmosphere using an air conditioner. There are different types of air conditioning systems which are used as per requirement e.g. residential, commercial, industrial, pharmaceutical etc.

During this process air purification, humidity

control, ventilation to maintain level of oxygen, odours free space, velocity of air (CFM, FPM, cubic m/h etc), proper distribution of air and temperature controll all these parameters are controlled.

An air conditioner is designed to control all these parameters simultaneously and automatically to meet human comfort requirements and for both summer and winter seasons.

How an air conditioner works ?

There are four main components of refrigeration or air

conditioner.

1. Compressor

2. Condenser

3. Expansion valve or capillary tube

4. Evaporator

Compressor is

called heart of refrigeration cycle. Compressor has two ports one is for

suction and other is for discharge. Compressor discharge the refrigerant to condenser (outdoor

unit ) at a high pressure and high temperature. At this stage the refrigerant

gas is in vapor form and when it starts to pass through the condenser it looses

its temperature and comes in liquid form but pressure remains the same. After

passing through the condenser refrigerant starts to pass through the expansion

valve or capillary tube. Here is the hidden truth. This is the basic principle

of gases that if gases are expanded in vacuum they lose temperature, same

principle applies in air conditioning and Refrigeration. The expansion valve

has very small dia through which refrigerant with high pressure tries to pass

but because of tiny space it tends to lose its velocity and suction pressure of

compressor start expanding this refrigerant due to which refrigerant's

temperature goes down and cooling effect is produced. When this refrigerant

with low pressure and low temperature passes through the evaporator (indoor

unit like split ac) it again gains the heat and space gets cool due to blower

which is circulating room's air on its coils. If humidity level (moisture) is

high in air, cooling and dehumidification process is performed by air

conditioner. When room's air is circulated over the cooling coil of evaporator

(indoor unit) humidity content starts to condense over the coils and starts to

flow through drain pipe in the form of water. This process in called cooling

and dehumidification, so there is no separate humidifier installed in air

conditioner.

Expansion valve:- An expansion valve is used in refrigeration or

air conditioning cycle to control the refrigerant flow. To produce cooling

effect in evaporator it is necessary to drop the pressure of refrigerant coming

from the condenser with low temperature but high pressure. When refrigerant

passes through the small dia of expansion valve or capillary tube its pressure

drops and suction pressure from compressor makes the refrigerant gas to expand.

This expansion causes the cooling effect in the evaporator.

After passing through the expansion valve the refrigerant with low

pressure and low temperature passes through the evaporator. Where evaporation

of refrigerant happens and cooling effect is produced in the conditioned space.

As the refrigerant in the evaporator starts to boil and is converted into vapor

form. Evaporator is known as cooling coil as well in indoor unit. Evaporator

and condenser work same like an heat exchanger and are same in construction

with combination of copper tubes and fins, but produce different effects.

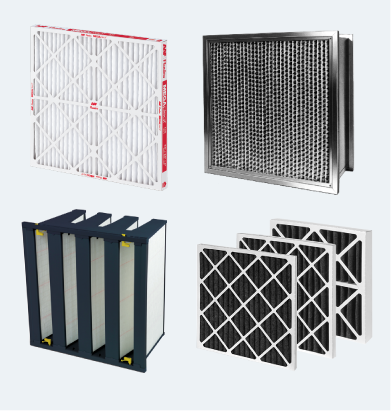

What is air purification or what are filters in air conditioning?

Air purification is very important factor which is considered while designing air conditioning systems. During air conditioning process air filtration is done by installing different kind of filters according to air volume and type of air conditioning systems. These filters keep the air free from contamination, germs and pollutants which can harm human health.

What is humidity or humidity ratio and how it is controlled ?

The quantity of water vapors present in air is called humidity and it is measured in percentage %.

With following example the term humidity is easy to understand

When we put a glass of chilled water in an open space the water content present in air starts to condense on the surface to glass. It happens due to low temperature on surface of glass and when water vapors in gaseous form with high temperature comes in contact with surface of glass the water vapors start to convert into liquid form and condense on the surface of water.

This process is called dehumidification.

Humidity during winter!

During winter season the condensation of water on surface of glass with chilled water will be lowest because the humidity levels are low. At lower temperature the water in our surrounding doesn’t evaporate and doesn’t mix up with air in vapor form.

Humidity during summer!

During summer season the condensation of water vapors on surface of glass with chilled water will be more as compared to winter season because water in our surrounding starts to evaporate due to high temperatures. But still the humidity level remains low and desert coolers gives their good performance to achieve human comfort zone.

Humidity during raining or monsoon season!

During monsoon season the condensation of water vapors on the surface of the glass with chilled water will be highest. The condensation happens very fast because due to rain and high temperatures the quantity of water vapor in gaseous form is all time high. The desert coolers are failed to perform well in this time period and we don’t feel comfortable or comfort zone can’t be achieved. It is noticed that our body sweats a lot but due to high quantity of water vapors in the air in our surrounding it doesn't dry and we feel very discomfort.

Always remember, Latent heat is directly related to humidity or water vapors ok !

To achieve human comfort zone during monsoon we need air conditioner. As soon as the air passes through the cooling coils of an air conditoner humidity or water vapors from air are separated efficiently and when air is circulated again and again the humidity level is easy to achieve according to design conditions.

What is Ventilation and why we need it in air conditioning process ?

Ventilation is the process which is required to achieve proper air quality in conditioned space and it's a process in which human health and human comfort are very important to consider.

An air conditioned space is always kept air tightened or sealed to avoid cooling lose from the conditioned space.

For example: - if we leave a window open of a room which is air conditioned, what will happen? The conditioned air will start to escape to the open area or atmosphere and cooling lose will happen which will affect the working performance of air conditioner and compressor will run for longer time to achieve the set temperature on the remote controller or wired controller. To avoid this lose the space is kept well air tightened.

But, if this space is occupied, what will happen?

Human body produces carbon dioxide by different processes. In this air tightened space occupants will start to feel discomfort due to release of carbon dioxide from their bodies. The air conditioning systems are designed to circulate the air in the space again and again over the cooling coil. If there will be not addition of fresh air in the space, it can lead to health issues. So to avoid this problem which can lead to health issues, ventilation is introduced in the system by different means. Either a duct will be provided to bring the fresh air to the air conditioning system where it will mix up with return air and thus the ventilation is achieved.

There are different methods or different types of ventilation systems which are used on the bases of application or type of building requirements.

An air conditioning unit is installed to produce human comfort zone. An air conditioner doesn't only produce temperature effects but it purifies and dehumidifies or humidifies air simultaneously. And an air conditioner can controll the humidity very effectively as compared to any other equipment.

Odor free space:- In an air conditioned space it’s important to stop the odors to mix up with the air. So the space is always kept air tightened and free from any leakages. The drain pipes which carries the condesed water from the air after passing the cooling coil is always provided with a U-trap to avoid any odor entering in the space through this pipe.

Air velocity control:- What will happen when cool air with high velocity strikes our body? Obviously, we will not feel comfortable and will move away from that space. To avoid this discomfort, air velocity is controlled to create a human comfort zone. At different locations of space which is to be air conditioned we need to maintain different air velocities to achieve properly balanced air conditioned space. This process is a part of HVAC design or calculations.

Proper air distribution and temperature controll:- In large buildings like hotels, shopping malls, theaters etc. The air distribution is done through a network of duct as shown in figure below. These ducts and air terminals are designed and selected by engineers to ensure proper air flow through the space as per ASHRAE requirements. If the air flow is well balanced and distributed properly then the temperatures can be easily achieved.

There are different types of air conditioning systems -

1.

DX Units :- DX stands for direct expansion means the type of an air

conditioner in which air directly falls on the cooling coil and refrigerant in

the cooling coil starts to evaporate. Most commonly air conditioners for home

or offices are DX units like window air conditioner, split air conditoner,

cassette air conditoner, VRF/VRV air conditioners or any other system in which

air directly takes cooling effect from cooling coils.

2.

Central air conditioning system:- Central air

conditioning system is the system where water is used to transfer cooling

effect from source to conditioned space like chillers.

1.1. Types of DX Units:-

Choosing an air conditioner is a bit cofusing thing for the people who don't have any idea about air conditioning systems. In this article I will share a very useful information which will help anyone to choose best air conditioner according to their place.

1.1.1. Split Air conditioner :- Split air conditioner consists of two parts one is

indoor unit and other is outdoor unit. Indoor unit is hanged on the wall of a

room and outdoor is placed or fixed outside the conditoned space. Split air

conditioner consumes more power and electricity bills can empty your pocket.

Because of long pipe runs cycle of refrigeration system becomes longer and it

increases the load on compressor. Split air conditioner has less longer life

and chances of leakage of gas are also high because of more joints in copper

pipe at the time of installation. Split air conditioner is good for office area

as it does not create sound. High installation and maintenance cost.

A split air conditioner may be ductable as shown in figure

below, means through ducting network air can be distributed to different

areas for air conditioning purpose.

Installation process-

1.1. Distance between outdoor and indoor unit connecting

copper pipes should not be more than recommended in my opinion not more that 5

meters.

1.2. Indoor unit should be fixed on the wall at a height not

more than 5feet 6inch and it should be in the exact center of the wall

horizontally.

1.3. Drain pipe should not be droped to an open area without

U-trap and use 1inch dia pipes for drain.

1.4. Outdoor unit should not be placed on the roof directly

exposed to sun. If possible choose north wall for the hanging of outdoor unit

as effect of sunshine in this direction is less as compared to other directions.

1.5. Out door unit should be hanged considering ease in

maintenance for the technician.

1.6. For outdoor units there should not be any wall or

obstruction near it to a distance of 3 meter in each direction.

1.1.2. Window Air conditioner :- A window air conditioner consists all components in a

single unit. All the required accessories and equipments are fixed in a single

body. Window air conditioner are more effecient as the gas cycle is small

because no separate outdoor unit is used and no extra copper piping runs. These

units dont need any copper joints as the product is completely ready to use by

the manufacturer. These units are a good choice for homes. Low installation

cost and maintence cost.

Installation Process :-

2.1. Installation of window air conditioner is very simple as

compared to split air conditioner system. Try to fix it in the window in the

north direction.

2.2. It can be placed at a height of not more than 5.5 feet.

2.3. It can only be installed in a window because condenser

side is always kept outside to release the heat in atmosphere. If its kept

inside a room it will produce heating and cooling in same amount and after some

time it will stop working because of less air circulation arround the condenser.

2.4. Window air conditioner should be installed in a window

in such a way that no gap remain between AC body and window. It should be

properly air sealed so that cooling lose may not happen.

5 star rating window AC are best

selection low power consumption.

1.1.3.

Cassette air conditioner :- A cassette air

conditoner is much similar to wall split air conditioner but indoor unit is

totally different in shape and its function. A cassette air conditioner indoor

unit can be hanged on ceiling using proper anchor fastners and threaded rods as

shown in figure below. Indoor units can through air through a horizontal blower

in two or four way directions as per requirement and return air is sucked from

center grills to maintain air circulation and air conditioning effect as shown

in figure below. This type of air conditioner is very quite and are very power

efficient. The copper piping system is designed to work with refrigerant gas or

chilled water too.

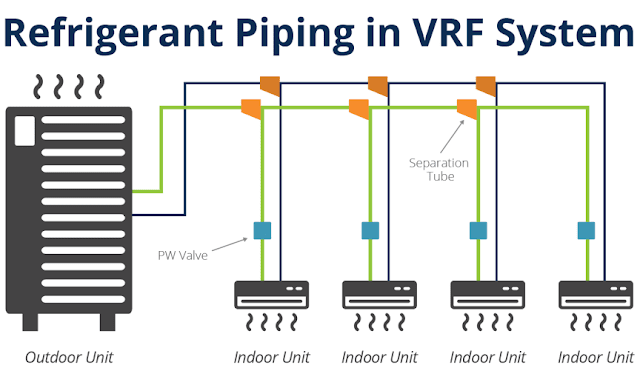

1.1.4. VRF/VRV (VARIABLE REFRIGERANT FLOW/VARIABLE REFRIGERANT VOLUME) :-

Variable refrigerant flow (VRF), also known as variable refrigerant volume (VRV), is an HVAC technology invented by Daikin in 1982. Like ductless mini-splits, VRFs use refrigerant as the cooling and heating medium. This refrigerant is conditioned by a single outdoor condensing unit, and is circulated within the building to multiple indoor units.VRFs are typically installed with an Air conditioner inverter which adds a DC inverter to the compressor in order to support variable motor speed and thus variable refrigerant flow rather than simply perform on/off operation. By operating at varying speeds, VRF units work only at the needed rate allowing for substantial energy savings at partial-load conditions. Heat recovery VRF technology allows individual indoor units to heat or cool as required, while the compressor load benefits from the internal heat recovery. Energy savings of up to 55% are predicted over comparable unitary equipment. This also results in greater control of the building's interior temperature by the building's occupants.

Working principle & Block diagram for various types of

VRF/VRV system: There are various types of VRF system used for split air

conditioning system.

1. Only Cooling type VRF system

2. Heat Pump VRF system (2 pipe system)

3. Heat Recovery VRF system (3 pipes system)

4. Hybrid VRF system

1. Only Cooling type VRF system:-

2. Heat Pump VRF/VRV system:- This system works for cooling and

heating both operation but not simultaneously. It is also known as 2 pipe

system. In this system all zones or all indoor units must either be all in

cooling or all in heating.

3. Heat Recovery VRF/VRV system:- Heat Recovery (HR) systems have

the ability to simultaneously heat certain zones while cooling others; this is

usually done through a three pipe design, with the exception of Mitsubishi and

Carrier who are able to do this with a 2 pipe system using a Branch Circuit

(BC) controller to the individual indoor evaporator zones. In this case the

heat extracted from zones requiring cooling is put to use in the zones

requiring heating. This is made possible because the heating unit is

functioning as a condenser, providing sub-cooled liquid back into the line that

is being used for cooling. While the heat recovery system has a greater initial

cost, it allows for better zoned thermal control of a building and overall

greater efficiencies. In heat recovery VRF systems, some of the indoor units

may be in cooling mode while others are in heating mode, reducing energy

consumption.

4. The Hybrid VRF:- This is world's first simultaneous heating and

cooling 2-pipe system that uses refrigerant between the outdoor unit and the

HBC (Hybrid BC controller), and water between the HBC and the indoor units. HBC

is the most unique part in this system and allows heat exchange between

refrigerant and water. This system is suitable for a wide variety of

installations. Mitsubishi and Carrier who are able to do this with a 2 pipe system

using a Branch Circuit (BC) controller to the individual indoor evaporator

zones. HVRF uses advanced refrigerant technology between the outdoor unit and

the HBC (Hybrid BC controller). Energy is then transferred around the building

using a pair of plastic water pipes per indoor unit that can supply hot or cold

water. This reduces the resources required for installation and provides a more

comfortable environment.

The following major Equipment & Accessories used in VRF/VRV

system:

1. VRF air cooled condensing unit (VRF outdoor unit)

Manufactures: Samsung, Mitsubishi, Trane, LG, Johnson control

(YORK), Toshiba, Daikin, Bosch, Gree, Hitachi, Voltas, O-general, Blue-star

etc.

Specification: Air cooled inverter scroll compressor based

variable refrigerant flow/volume (VRF/V) air conditioning system suitable for

Heating & Cooling (Heat pump or Heat Recovery) outdoor condensing unit with

at least one inverter type compressor in each module with R410a refrigerant,

suitable for 380-415 V, 3 Ph, 50 Hz supply complete with condenser coils,

condenser fans, Electronic expansion valve, Solenoid valve, 4 way reversing

valve, Distribution headers & capillaries, Filters, Shut-off valve, Oil

coolers, Service ports, Refrigerant receiver & accumulators, inverter based

microprocessor controller, including connection with outdoor unit

multi-connection piping kit etc.

Capacity Range: VRF outdoor capacity ranges from 6 – 20TR (6 TR, 8

TR, 10 TR, 14 TR etc)

2. Fan coil unit (Indoor unit)

Manufacturer: Samsung, Mitsubishi, Trane, LG, Johnson control

(YORK), Toshiba, Daikin, Voltas, O-general, Hitachi, Lloyd, Videocon, Blue-star

etc.

Specification:- Indoor unit equipped with fan section with low

noise fan, multi speed motor, coil section with DX coil, Electronic expansion

valve, Pre-filters, Epoxy coated outer cabinet, drain pan, corded remote

controller, Y-joint header & Flaring set etc.

Capacity range: Decorative wall mounted FCU = 0.8 TR, 1.0 TR, 1.5

TR Decorative ceiling suspended FCU = up to 4.0 TR Ducted ceiling suspended

concealed type FCU = 2.0 TR to 8.0 TR Cassette type FCU = up to 4.0 TR Floor

mounted Decorative type FCU = 4.0 TR to 10.0 TR

3. Hybrid Branch Controller (HBC):- The HBC (Hybrid BC controller)

allows simultaneous cooling and heating of Hybrid systems by connecting several

indoor units to one outdoor unit using only two pipes. It has a built in heat

exchange between refrigerant and water. Plastic water pipe is then used between

the HBC and the indoor units.

4. Separation Tube Assembly (STA):- VRF piping improves refrigerant

cycle efficiency and reduces piping cost by connecting multiple indoor units to

a common liquid and suction line through the use of Separation Tube Assemblies

(STA) and/or Headers which diverts the common flow of refrigerant to

an individual evaporator. The flow of refrigerant is further metered by an

EEV or Electronic Expansion Valve.

5. 4 way reversing valve:- A heat pump reversing valve is an

electro-mechanical 4-way valve that reverses the refrigerant (Freon) flow

direction, using an electrical magnet. Frist let’s see what a heat pump

reversing valve looks like. In the figure below, you will notice the valve has

4 tubes or connections; A, B, C, D. This valve is also referred to as a 4-way

valve.

Cooling Mode (Energised mode):- The heat pump reversing valve has 4

large tubes (A, B, C, D ) that’s why they call it a 4 way valve and it also

has:- capillary tube (1), capillary tube (2), capillary tube (3), slider (4),

block (5) ,electrical coil (6), electrical magnet (7), and spring (8). Notice

that the compressor’s discharge port (high pressure) is always connected to

tube A in the reversing valve and the return port (low pressure) in the

compressor is always connected to tube B.

Therefore tube A always has higher pressure refrigerant, and tube

B always has lower pressure refrigerant. Notice also that capillary (2) is

always connected to tube A, thus capillary (2) also has a high pressure. When

we energize the electrical coil (6) it energizes the magnet (7) that pulls the

block (5) which will blocks the capillary tube (3) and compresses the spring

(8). Got it? Great, so notice that the capillary tube (3) is now blocked, and

the high pressure refrigerant will flow from capillary (2) to capillary (1)

straight to the left side of the heat pump reversing valve’s body that will

push the slider to right hand side from the valve’s body which will allow the

high pressure refrigerant to go from the tube A to tube D to the outdoor coil,

through the metering device to drop its pressure, then to the indoor coil to

cool the inside of the house (cooling mode) then back to tube C. If you had

notice the slider has a top groove which allows the low pressure refrigerant to

flow from tube C to tube B then back to the return port in the compressor to

repeat the cycle again.

Heating Mode (De-energised mode):

Please notice that the coil (6) lost its power, or de-energized,

which makes the electrical magnet (7) lose its magnetic power. When this

occurs, the spring (8) will decompress and push the block (5) to the left, and

block the capillary tube (1). I am thinking you are becoming an expert by now!

The capillary tube (1) is now blocked and the high pressure

refrigerant will flow from capillary (2) to capillary (3) straight to the right

side from the reversing valve’s body. This in turn will push the slider to the

left hand side of the valve’s body which will allow the high pressure

refrigerant to go from the tube A to tube C. This allows refrigerant to flow to

the indoor coil to heat the inside of the house (heating mode), then through

the metering device to drop its pressure then to the outdoor coil then back to

tube D. Again the slider has a top grove this will allow the low pressure

refrigerant to flow from tube D to tube B then back to the return port in the

compressor to repeat the cycle again. That’s it that’s how the heat pump

reversing valve works in real-life.

6. Electronic Expansion Valve (EEV):- Electronic expansion valves

replace mechanical expansion devices, improving control of refrigerant flow and

consequently increasing unit efficiency by up to several percent. Moreover, these

also have statistical advantages again of several percent as the electronic

system guarantees optimum calibration at all times, unlike mechanical devices

that needs to be adjusted manually and periodically.

7. Non Return Valve (NRV) for Refrigerant flow: NRV can be used in

liquid, suction and hot gas lines in refrigeration and air conditioning plants

with fluorinated refrigerants. NRV can be supplied with flare and solder

connections to make one directional refrigerant flow in the system.

8. Refrigerant Piping:- Copper tubing is most often used as

refrigerant line in HVAC systems. There are two basic types of copper tubing,

soft copper tube (Type-L) and hard copper pipe (Type – K). Copper tubing is

joined using flare connection, compression connection, or Brazing. Copper

offers a high level of corrosion resistance, but is becoming very costly. Soft

(Type - L) copper tubing with medium thick wall can be bent easily to travel

around obstacles in the path of the tubing. This type of copper tubing suitable

for flare connections. Soft copper is the most popular choice for refrigerant

lines in split-system air conditioners and heat pumps for small run of

refrigerant piping (Horizontal up to 3 mtr). Flare connection is mostly used

for soft copper tube connection.

Hard copper tubing (Type – K) is mostly used for long run of

horizontal/vertical refrigerant piping. Hard copper tube is of thick walled and

hence cannot be bend and must use various copper fitting such as elbow, reducer

and sockets to make a turn, reduce & connect other piece of pipe

respectively. Soldering are mostly used for hard pipe connection.

Types of Copper piping connections:

1. Brazing connection:- This joint is heated with a torch using the

mixture of oxygen & acetylene gas, and copper alloy filler is melted into

the connection. When the brazed joint cools, it forms a very strong bond which

can last for decades.

2. Flare connection:- Flare connections require that the end of a

tubing section be spread outward in a bell shape using a flare tool. A flare

nut then compresses this bell-shaped end onto a male fitting. Flare connections

are a labour-intensive method of making connections, but are quite reliable

over the course of many years.

3. Compression Fitting:- Compression fittings use a soft metal or

thermoplastic ring which is squeezed onto the pipe and into the fitting by a

compression nut. The soft metal conforms to the surface of the tubing and the

fitting, and creates a seal.

9. what is insulation for Refrigerant pipes ?

1. Nitrile Rubber Insulation:- Nitrile-rubber foam insulation that is closed cell, flexible and has a built-in vapour barrier. Density with 60kg/m3, working temperature range -200 to 115 ℃, thermal conductivity 0.037 W/m⁰K and resistance to oil & grease. Insulation tubes are available in size ¼” – 4” of length 2 mtr with insulation thickness 9mm, 13mm, 19mm, 25mm. This is widely used in HVAC refrigerant piping insulation.

2. Polyurethane foam (PUF):- PUF pipe insulation with density

36 kg/m3 and thickness ranges 25 -100 mm with facing of aluminium foil or kraft

paper is widely used for Pipe and duct insulation.

3. Polyethylene Foam (PEF):- Polyethylene Foam is a strong and

resilient closed cell foam available in sheets, tubes & cylinders. It is

widely used in HVAC piping for light weight, super strength & tear

resistance

1.1.5.

Packaged air conditioner:- A packaged air

conditioner is similar to a window AC, all the components are installed in a

singly body but packaged air conditioner is used for large areas like halls,

offices, shoping outlets, marriage palaces or a big house. A package air

conditioner needs ducting system to deliver conditioned air to space and

retrurn air from the space returns to the units by duct or by path through

which supply air duct is passed. A packaged air conditioner may contain single

circuit, double circuit or three circuits piping networks and for each

circuit an individual compressor is installed.

A chiller is widely use in high rise buildings like hotels, shoping malls, Hospitals etc for air conditioning. Chillers are used for high cooling capacities requirements in industries as well. A chiller may be water cooled or air cooled means the condensation of refrigerant is done either by air or water through cooling towers. An individual plant room is considered for placement of these chillers in building. The water is circulated through FCUs, AHUs or any other indoor unit through piping network using Pumps. Water works as a medium for air conditioning instead of refrigerant. The refrigerant only circulates in copper piping network in chiller and water circulates through all over the building.