What is HVAC or what do you understand by HVAC?

HVAC stands for Heating Ventilation and Air Conditioning or it can be defined as a combination of Heating, Ventilation and Air Conditioning processes to create human comfort zone. This industry is very vast in itself as there are many different types of HVAC systems. These systems are used in residential, commercial, industrial, pharmaceutical, marine, space and airlines industry as well. Human comfort zone can’t be achieved only by using air conditioning systems in large buildings like hotels, cinema halls, airports or any other multistory buildings. Because of large volume of air inside the building which needs proper exhaust and proper fresh air intake to maintain air quality inside the space. Heating and cooling of air is used as per requirements or according to required temperatures in air conditioned space. In summer we need cooling and in winter we need heating systems but Ventilation is used in both the two processes to complete the process of HVAC.

What is human comfort zone ?

The human comfort zone is a space created for human comfort where air temperature, air flow or velocity of air, air quality and bacterias are controlled. Phsychrometeric study of air is done prior to design or selection of an air conditioner for any building or space for human comfort.

Basic parameters of human comfort zone are as following: -

1. Dry bulb temperature - 75 deg. F or 24 deg. C

2. Relative Humidity - 50%

3. Air velocity - 700 - 800 FPM

4. Noise criteria - 35-40 dba

What is heating in ?

As the name heating suggests, it’s one of the process to raise the temperature of air to produce heating effect in a building to achieve human comfort zone. There is a source of heat in the building which produces heat energy and this energy is distributed uniformly in the building by using water or air as a medium of heat transfer. This source to produce heat energy may be a heat exchanger or a boiler. There are different types of heat exchangers. Heating process is also achieved by using different types of advanced air conditioners which comes with an option to produce heating and cooling effects as per requirements. These systems are called heat pumps as well. These heat pumps use a four way reversing valve in its refrigeration cycle which diverts the flow of refrigerant to produce cooling or heating effects.

What is Ventilation process?

Human body produces carbon dioxide by different processes. All air conditioned spaces are kept air tightened to reduce cooling or heating effects. But in air tightened spaces occupants will start to feel discomfort due to high level of CO2 (carbon dioxide), released from their bodies by different processes of human body. Thess systems are designed to circulate the air in the space again and again over the cooling coils and have an inlet section for fresh air to mix up with return air coming from the air conditioned space. If there will be not addition of fresh air in the space, it can lead to health issues. So to avoid this problem which can lead to health issues, ventilation is introduced in the system by different means. Either a duct will be provided to bring the fresh air to the air conditioning system where it will mix up with return air and thus the ventilation is achieved.

In an air conditioned space it’s important to stop the odors to

mix up with the air. So the space is always kept air tightened and free from

any leakages.

Different methods of Ventilation

What is air conditioning process?

In very simple words term air conditioning is a process to create human comfort zone. Air conditioning is not only concerned to temperature control but in this process all psychrometric properties and parameters of air are considered. The basic principle of thermodynamics is, heat energ

y always transfers from hot substance to cold substance. And this basic principle is applied in air conditioning process as well. The heat is abstracted from the conditioned space and released outside to the atmosphere using an air conditioner. There are different types of air conditioning systems which are used as per requirement e.g. residential, commercial, industrial, pharmaceutical etc.

During this process air purification, humidity control, ventilation to maintain level of oxygen, odours free space, velocity of air (CFM, FPM, cubic m/h etc), proper distribution of air and temperature controll all these parameters are controlled.

An air conditioner is designed to control all these parameters simultaneously and automatically to meet human comfort requirements and for both summer and winter seasons.

HVAC APPLICATIONS

Residential systems: -

Most commonly for residential application only air conditioning systems are used instead of complete HVAC system because the area is small and so the volume. Complete system is installed, where the house area and volume is large and ventilation needs to be done separately. There are different types of air conditioners which are used for residential applications.

Only cooling air conditioners: -

These types of air conditioners are specially designed for a particular operation of cooling only and are used in summer for human comfort. These air conditioners are not designed to produce heating effect as a complete HVAC system requires for winter season. These air conditioners are good for the weather conditions where temperature in summer is usually high (35-40°C) and during winter the temperature doesn’t go below 6-7°C. Only cooling air conditioners are widely used in Middle Eastern and Asian countries where summer period is long and temperatures go high up to 48°C.

Following are some images of window and hi-wall air conditioners which are commonly used for residential air conditioning.

Heat Pump air conditioners: -

Heat pump air conditioning systems are designed to perform both cooling and heating processes. These air conditioners are widely used in the countries where temperatures in summer are high and in winter the temperatures drop down below freezing point. These air conditioners are equipped with a four way reversing valve which controls the operation of heating and cooling. These air conditioners produce heating and cooling effects according to comfort requirements.

Commercial systems

For large buildings like cinema theaters, auditoriums, palaces, hotels, gyms, offices, etc where occupancy levels are usually high, commercial HVAC systems are introduced to achieve human comfort zone.

There

are different types of commercial HVAC systems:-

Single Split air conditioners

Split air conditioners are similar to residential air conditioners like split hi-wall, cassette air conditioners, ducted split, ceiling suspended etc. These HVAC systems can be used for air conditioning processes for small offices, meeting halls etc. But Ventilation is also done by using exhaust and fresh air ducts to meet complete HVAC systems. For the geographical conditions where requirements are both for heating and cooling according to the weather cycles, there we use heat pumps. But if the requirement is only for cooling there we use only cooling air conditioning systems. For single split air conditioners, each system has one outdoor and one indoor individually.

Multi split air conditioners

These systems are designed to use only one outdoor unit which can be connected to 9-10 indoor units and numbers of indoor systems can be increased depending on the requirement and capacity of the systems. These systems can be used for large office spaces, cafes, motels, small hotels etc. These systems have a little expensive installation cost but operating cost is lower than single multi splits air conditioning systems.

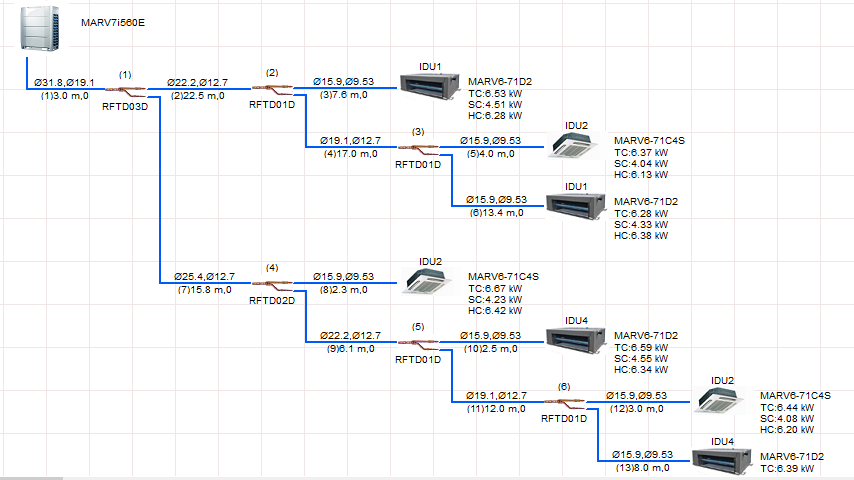

VRF/ARV air conditioning systems

Variable refrigerant flow (VRF), also known as variable refrigerant volume (VRV), is a part of HVAC technology invented by Daikin in 1982. As in ductless mini-splits, VRF/VRV systems use refrigerant as the cooling or heating medium as per requirements depending on the weather and indoor temperature requirements. These systems use one outdoor unit or more than one in modular connections depending on the number of indoor units. The condensation process of the refrigerant is done by a single outdoor unit, and is circulated within the building to multiple indoor units.

Working principle & Block diagram for various types of VRF/VRV system: There are various types of VRF system used for split air conditioning system.

1. Only Cooling type VRF system

2. Heat Pump VRF system (2 pipe system)

3. Heat Recovery VRF system (3 pipes system)

4. Hybrid VRF system

1. Only Cooling type VRF system:-

2.

Heat Pump VRF/VRV system:- This system works for cooling and

heating both operation but not simultaneously. It is also known as 2 pipe

system. In this system all zones or all indoor units must either be all on

cooling or all on heating mode.

3.

Heat Recovery VRF/VRV system:- Heat Recovery (HR)

systems have the ability to simultaneously heat certain zones while cooling

others; this is usually done through a three pipe design, with the exception of

Mitsubishi and Carrier who are able to do this with a 2 pipe system using a

Branch Circuit (BC) controller to the individual indoor evaporator zones. In

this case the heat extracted from zones requiring cooling is put to use in the

zones requiring heating. This is made possible because the heating unit is

functioning as a condenser, providing sub-cooled liquid back into the line that

is being used for cooling. While the heat recovery system has a greater initial

cost, it allows for better zoned thermal control of a building and overall

greater efficiencies. In heat recovery VRF systems, some of the indoor units

may be in cooling mode while others are in heating mode, reducing energy

consumption.

4.

The Hybrid VRF:- This is world's first simultaneous heating and cooling

2-pipe system that uses refrigerant between the outdoor unit and the HBC

(Hybrid BC controller), and water between the HBC and the indoor units. HBC is

the most unique part in this system and allows heat exchange between

refrigerant and water. This system is suitable for a wide variety of

installations. Mitsubishi and Carrier who are able to do this with a 2 pipe

system using a Branch Circuit (BC) controller to the individual indoor

evaporator zones. HVRF uses advanced refrigerant technology between the outdoor

unit and the HBC (Hybrid BC controller). Energy is then transferred around the

building using a pair of plastic water pipes per indoor unit that can supply

hot or cold water. This reduces the resources required for installation and

provides a more comfortable environment.

The

following major Equipment & Accessories used in VRF/VRV system:

1.

VRF air cooled condensing unit (VRF outdoor unit)

Manufactures:

Samsung, Mitsubishi, Trane, LG, Johnson control (YORK), Toshiba, Daikin, Bosch,

Gree, Hitachi, Voltas, O-general, Blue-star etc.

Specification:

Air cooled inverter scroll compressor based variable refrigerant flow/volume

(VRF/V) air conditioning system suitable for Heating & Cooling (Heat pump

or Heat Recovery) outdoor condensing unit with at least one inverter type

compressor in each module with R410a refrigerant, suitable for 380-415 V, 3 Ph,

50 Hz supply complete with condenser coils, condenser fans, Electronic

expansion valve, Solenoid valve, 4 way reversing valve, Distribution headers

& capillaries, Filters, Shut-off valve, Oil coolers, Service ports,

Refrigerant receiver & accumulators, inverter based microprocessor

controller, including connection with outdoor unit multi-connection piping kit

etc.

Capacity

Range: VRF outdoor capacity ranges from 6 – 20TR (6 TR, 8 TR, 10 TR, 14 TR etc)

2. Fan coil unit (Indoor unit)

Manufacturer:

Samsung, Mitsubishi, Trane, LG, Johnson control (YORK), Toshiba, Daikin,

Voltas, O-general, Hitachi, Lloyd, Videocon, Blue-star etc

Chillers in HVAC systems

Chillers are widely used in high rise buildings like hotels, large shopping malls, Hospitals etc. for air conditioning. Chillers are used for high cooling capacities requirements in industries as well. A chiller may be water cooled or air cooled means the condensation of refrigerant is done either by air or water through cooling towers. An individual plant room is considered for placement of these chillers in a building. The water is circulated from chiller to FCUs, AHUs or any other indoor unit through piping network using Pumps. Water works as a medium for air conditioning instead of refrigerant. The refrigerant only circulates in copper piping network in chiller and water circulates through all over the building.

Types

of chillers according to compressors

Reciprocating

compressor type chillers

Scroll

compressor type chillers

Screw

compressor type chillers

Centrifugal

compressor type chillers